M70- Barber Green 300-350 TPH Drum-

Portable Tandem Axle, 8 x 41 ,PF with RAP Collar, Gravity Feed Drum, 50% left on Ring Gear, 100 HP motor with newer Planet Gear Reducer, Hauck SJO 460 Combo Burner with 100 HP 360oz Blower, fuel type- nat. gas.

1996-Protecaire Pulse Jet Baghouse-model- 55/L (Approx. 55,000,00 ACFM)

Stationary 3-section house. 435 bags are not included with the house, but the cages are. Twin City BCS-SW Size 490 Backwards Incline Fan (no motor), single auger 10 HP dust discharge auger. A Quincy OGD 50 HP Rotary Screw Compressor supplies air to the pulsing system.

Asphalt Storage (250 Tons +/-)

Portable 100-ton Barber Greene Silo (AS110x142) with 5-ton Weigh Batcher, Anti-Segregation Batcher. Stationary 150-ton Silo with 3-ton Weigh Batcher, Anti-Segregation Batcher. Barber Greene. A Barber Greene portable dual-chain hot elevator, driven by a 75 HP drive package, delivers material to an incline double-chain slat conveyor from the 100-ton silo to the 150-ton silo.

A.C. System

One (1) 17,900-gallon portable A.C. Tandem Axle Tank, no heater, metering skid, A.C. lines.

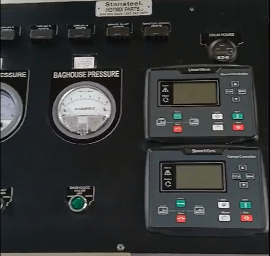

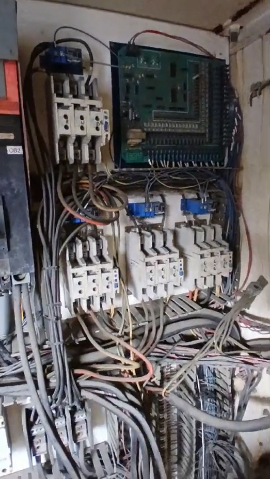

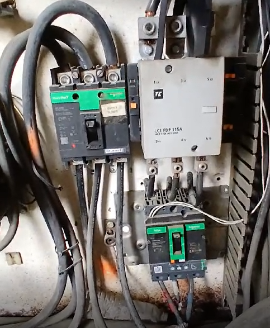

Controls

No control house. A PLC panel is provided with burner control and baghouse control for the plant, along with a second panel with EZ Blend Digi Blend Mixing Controls and a panel to accommodate up to 6 cold feed/RAP controllers, plus some start/stop controllers. There are also some D.C. controllers for cold feed bins (no bins included). No MC center included.

Miscellaneous Items

Included are duct work from the drum to the baghouse, baghouse auger, some natural gas lines (no gas train), ladders, legs, etc.

Please Note:

At best, we have some components, but this is not a complete plant. The drum is an older, large PF drum with no slinger belt. The silo system is mismatched (with a bucket elevator). The A.C. tank is small, and the heating source is uncertain (could be DF, indirect, or electric—though it looks electric, why the propane tank?). There is no control house, no MC center, older automated controls, no wiring, no fuel source for the burner, no screens or conveyors, and no cold feed bins.